Texas Rig Equipment is an authorized service center for multiple top pump and hydraulic manufacturers. Our technicians are trained to repair and troubleshoot all brands of pumps, power frames, hydraulics, gear drive systems, clutches and much more to OEM specs.

With our comprehensive inventory on-hand and our machining capabilities we will minimize your company’s downtime with the quickest turnaround possible. All repairs and remanufactured products are hydrostatically tested, giving customers assurance of quality work in all mechanical components.

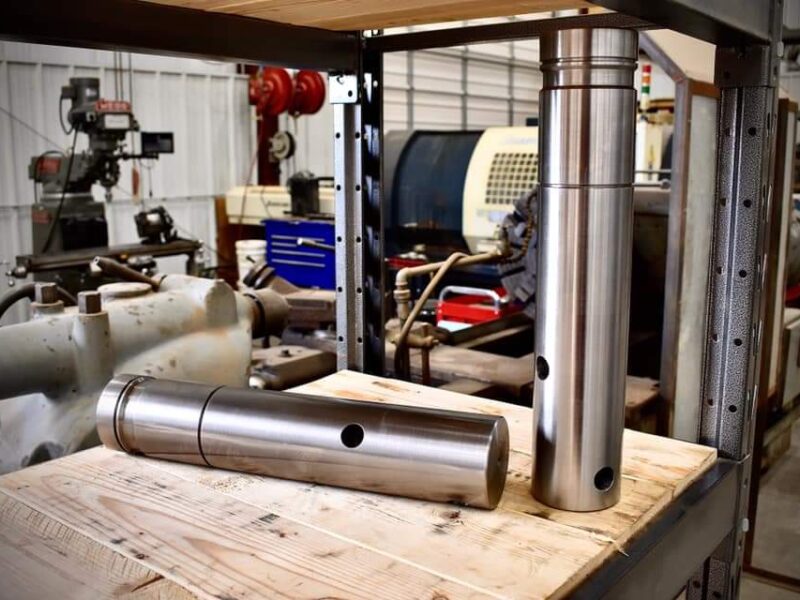

Machining/Fabrication

Our machining and fabrication department not only assists in rebuilding and repairing hydraulic stimulation frac pumps but also fabricates a wide range of equipment specified by our customers in the oil & gas industry as well as construction, agriculture, pipeline, trucking/transport and mining. TRE will repair your product back to factory specifications. After a review from our engineering department our experienced fabrication team will construct per the customer’s drawing anything that you require.

- Welding Processes available: MIG, TIG, STICK

- Cutting Processes available: Plasma, CNC Plasma, Oxy/Acetylene

Machining Capabilities

With our CNC and manual machines, we will make sure your product meets your required specs. Our Milling department encompasses everything from small vertical Bridgeport mills to large Lucas and Giddings & Lewis horizontal boring mills with a capacity of up to 30,0000 lbs. Our Axelson lathes have up to a 24” chuck and 102” bed. With our Pratt & Whitney vertical shaper we can machine internal surfaces, keyways, slots, groves, squares, hexagons and straight-sided splines. The slotting process is also used for cutting exterior shapes and forms.

Plasma Cutting Services

Our Hypertherm powermax 125 plasma system with a 5 x 10 Piranha cutting table is capable of cutting: stainless steel, carbon steel, mild steel and aluminum as thin as 20 gauge and up to 1.25 inches thick with outstanding accuracy and efficiency.

We strive to provide quick turn arounds and get you the pieces you need as efficiently as possible. Our on-hand inventory of steel mean there is no delay in waiting for materials to arrive from an outside source before we can begin plasma cutting. Our clients that provide CAD drawings mean we can further expedite the fabrication process. Or you can bring in parts to be replicated, with our in-house CAD design services we can handle your project from start to finish.

Beyond plasma cutting Texas Rig Equipment offers a full metal fabricating processes, so if your project requires further manufacturing we can handle the job in-house. We truly are the one-stop-shop for all of your metal work needs. Please send all CNC inquires to our CAD design services team email: CNCservices@TexasRigEquipment.com

Parts

We sell a wide range of factory replacement parts as aftermarket parts. Bearings, Mechanical seal, oil seals, o-rings, impellers, babbitt bearings, plungers, pony rods, bearing housing, rebuild kits, shafts, hubs, couplings, valves, aluminum fuel cap extensions and much more.